Controlling Harmonics in Commercial Buildings and Hospitals

By: Subodh Bhatia, Westek Electronics Pty Ltd

There are some significant differences between industrial and commercial electrical installations when it comes to harmonics. The main features of a large proportion of factories, treatment plants, mining sites, etc are the power electronic loads. These include variable speed drives, induction heaters, plating baths, CNC machining centres, etc. A lot of these loads are powered by three-phase, three-wire circuits. Increasingly the suppliers of variable speed drives, to take but one example of power electronics, in particular the 6-pulse variety, are equipped with some form of harmonic suppression.

Things are very different in commercial installations. In the first place a large number of loads are single-phase, and therefore neutrals are everywhere. Four-wire circuits feeding many loads such as computers, electronic ballasts, etc have large neutral currents and in particular triplen harmonics (like the third harmonic) that flow in phase and return via the neutral. When you consider that balancing single-phase loads can be a very challenging task, the stress on neutrals is an even more important consideration.

The loads encountered in shopping malls, hospitals and commercial buildings in general have as their input stage, both linear and switch mode power supplies. Harmonics generated by a bridge-rectifier follow the rule of the harmonics number (h) being given by kP +/-1, where k is an integer (i.e: 1, 2, etc) and P is the number of pulses switching the rectifier elements during the AC cycle. For the bridge rectifier, P equals 4. The lowest harmonic is thus the third, followed by the fifth. For a three-phase, 6-pulse converter, and using the same formula, the lowest order harmonic is the fifth, the next order being the seventh, followed by the eleventh, etc.

The absence of the third harmonic is an important difference distinguishing the ubiquitous variable speed drives found in everything from bottling plants to grinding mills when compared to single phase electronic loads. It is not so that much less attention needs to be paid to harmonics mitigation in industrial situations—it’s more that mitigation takes a different approach (one could argue, a simpler approach) than for commercial installations.

Industrial solutions use reactors and passive filters to lower harmonic current contribution. Of course there are instances where broadband active filters are used, for example with large motor loads exhibiting large inrush current and in cases where there are large degrees of load variation but that is not the rule.

Correction for third harmonic and higher zero sequence harmonics requires active harmonic filtering BUT with special requirements imposed on the filter. In short this comes about because phases are never balanced in installations where equipment is continually being plugged in and unplugged. Active filtering works on the basis of supplying antiphase harmonic current thus minimising harmonic current in the circuit supplying the load. In the case of a commercial installation, the obvious correction point has to be at a sub-distribution level so that power loss in risers and ring mains can be avoided. The zero sequence harmonics unlike the 50 cycle three-phase current return via the neutral—even in a perfectly balanced circuit.

Effective active harmonic filtering requires that the harmonic components in each phase be monitored—AND—corrected. This important restriction is frequently overlooked when active filters are selected and although a so-called four-wire, three-phase filter may appear at first glance to be suitable it may not compensate effectively for the triplens because of the very dynamic situation that applies with tenancies in a typical shopping mall.

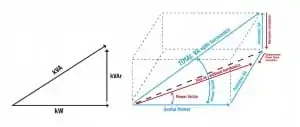

The power demand diagrams below explain graphically the operation of active harmonic filter harmonics mitigation. The diagrams show two situations. The figure on the left is the power triangle of a load without harmonics, for example an induction motor. The horizontal axis is the useful power axis and represents kilowatts drawn by the load. The vertical axis shows the reactive power drawn by the load in kilovolt-amps. The hypotenuse of the right-angle triangle shows the total demand in kilovolt-amps. Note that the three components of the triangle are all 50 Hz parameters. The diagram on the right is drawn as a three-dimensional figure with the reactive component due to harmonics at right angles to the plane in which the power triangle of a non-harmonic load is. This arises because the harmonic demand is at multiple frequencies of the 50 Hz fundamental.

It is important to note that not all active filters perform the same correction task. Shown here is that the active filter should operate with excess capacity available for displacement power factor correction. A critical parameter in electrical installations is that of flicker. This is caused by the switching in and out of loads, start up of heavy current drawing loads, and active filters need to have a broadband (global) correction methodology so that response within two-thousands of a cycle period is possible. The filters should also permit tailoring of the selective filtering of designated harmonics such as the fifth, and other negative sequence harmonics, which can cause mal-operation of direct-on-line motors.

It needs to be emphasized that the very first step for the application of mitigation measures is the analysis of harmonics in the various part of the installation. Predictive software for use with this analysis task is critically important. Increasingly supply authorities are insisting that voltage distortion at the customer’s connection point (point of common coupling—pcc) does not exceed the maximum values imposed by Australian Standards AS/NZS 61000.3.6. Frequently the effects at the pcc have not been within specifications even though reasonably effective mitigation measures had been adopted. Predictive analysis goes a long way in avoiding such situations.