How It Works:

The capacitor-based system monitors the power usage at the site and automatically switches in capacitor banks to compensate for the reactive power demand caused by inductive loads. This process typically operates in increments of 12.5 kVAr or 17 kVAr and can respond to changes in reactive load within 30 milliseconds. These systems are particularly effective in applications where equipment operates consistently, allowing for stable power factor correction.

Advanced Options:

For applications requiring faster response times—such as when motors quickly come under load (e.g., sawblades in sawmills)—the system can be enhanced with Thyristor switches. These switches provide quicker operation compared to traditional contactors, enabling a more immediate reaction to load changes.

Technical Specifications

General Specifications:

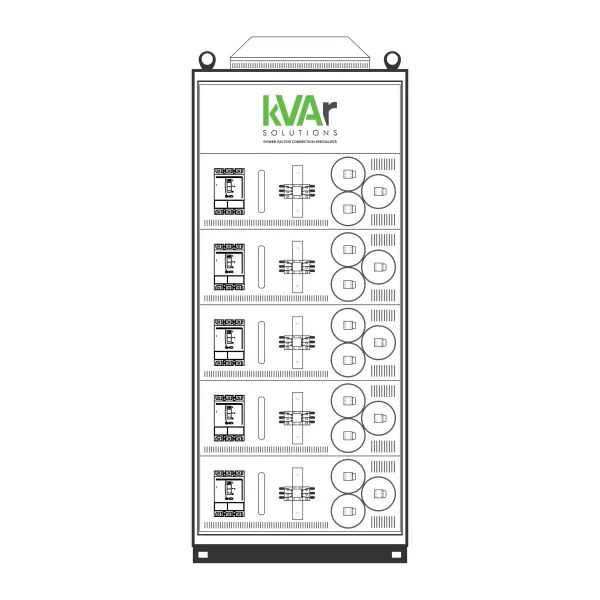

Product Type: Capacitor Based Power Factor Unit

Configuration: Up to 405 kVAr for standard systems and 300 kVAr for rapid systems

Design: 7-step unit with standard rearbus connection for easy hot-swapping of trays

Major Component Vendors: Rittal, KBR, Elektra, & Noark

Installed Cabinet Dimensions:

Height: 2,202 mm

Width: 792 mm

Depth: 578 mm

Weight: Over 500 kg

Operating Temperature: Up to 65ºC

Housing: Powder-coated mild steel (Rittal)

System Parameters:

Nominal Current: 1.35 x kVAr Rating

Rated Voltage: 415V

Power Frequency: 50Hz

Protective Device for Supply: 1.5 x nominal current

Performance & Mechanical Features:

Contactor: NOARK rated for tray size

Reactor: Elektra tuned at 187Hz

Operational Mode: Lagging

Switching Speed: 20 ms for rapid systems; 5-15 seconds for standard systems

Monitoring Capabilities: Modbus Communication

Cooling System: Thermostat controlled

Over Temperature Protection: Thermostat controlled

Tray (Step) Specifications:

Net Weight per Tray: Approximately 60 kg

Rated Voltage: 415/440V

Hot Swappable: Yes

kVAr Ratings Available:

Rapid Systems: 6.25, 12.5, 17, 25, 33, 50

Standard Systems: 6.25/12.5, 8.3/17, 12.5/25, 17/33, 12.5, 17, 25, 33, 50, 67

Warranty: 2 years for components, 5 years for workmanship

Applications:

Capacitor-based power factor correction systems are widely used in various industrial applications where power factor correction is crucial for operational efficiency. These include:

Motor and Pump Operations: Consistently running equipment benefits from stable power factor correction.

Manufacturing Facilities: Reducing reactive power demand improves overall energy efficiency.

Sawmills: Quick acting systems are particularly beneficial when machines experience rapid load changes.

Capacitor-based power factor correction systems provide an effective means of improving power factor, reducing energy costs, and enhancing the performance of electrical systems. Their reliability and straightforward operation make them suitable for various industrial applications, ensuring optimal efficiency and productivity.